Technology.

When it comes to 3D printing in Dubai, Generation 3d have led the technological revolution since 2015. As a pioneer in advancing the technology to fit the regions fast paced and demanding business climate, we have our own technology and work flows specifically designed in order to meet the regions needs.

As a 3D printing service provider, we ensure that all areas of our service are world class and we continue to innovate in all areas of our value chain.

Machinery

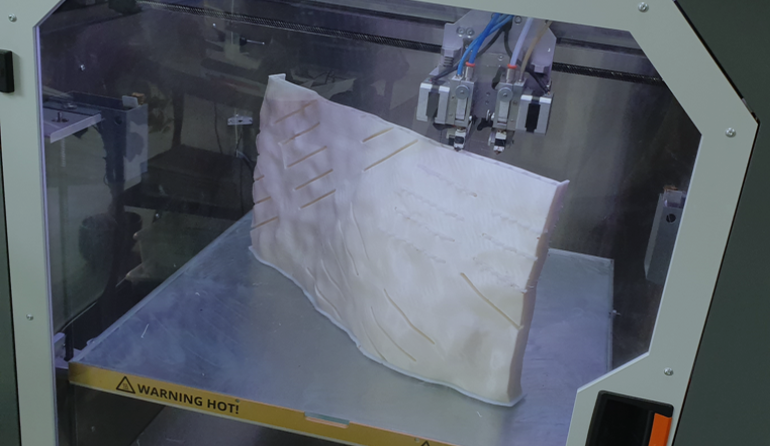

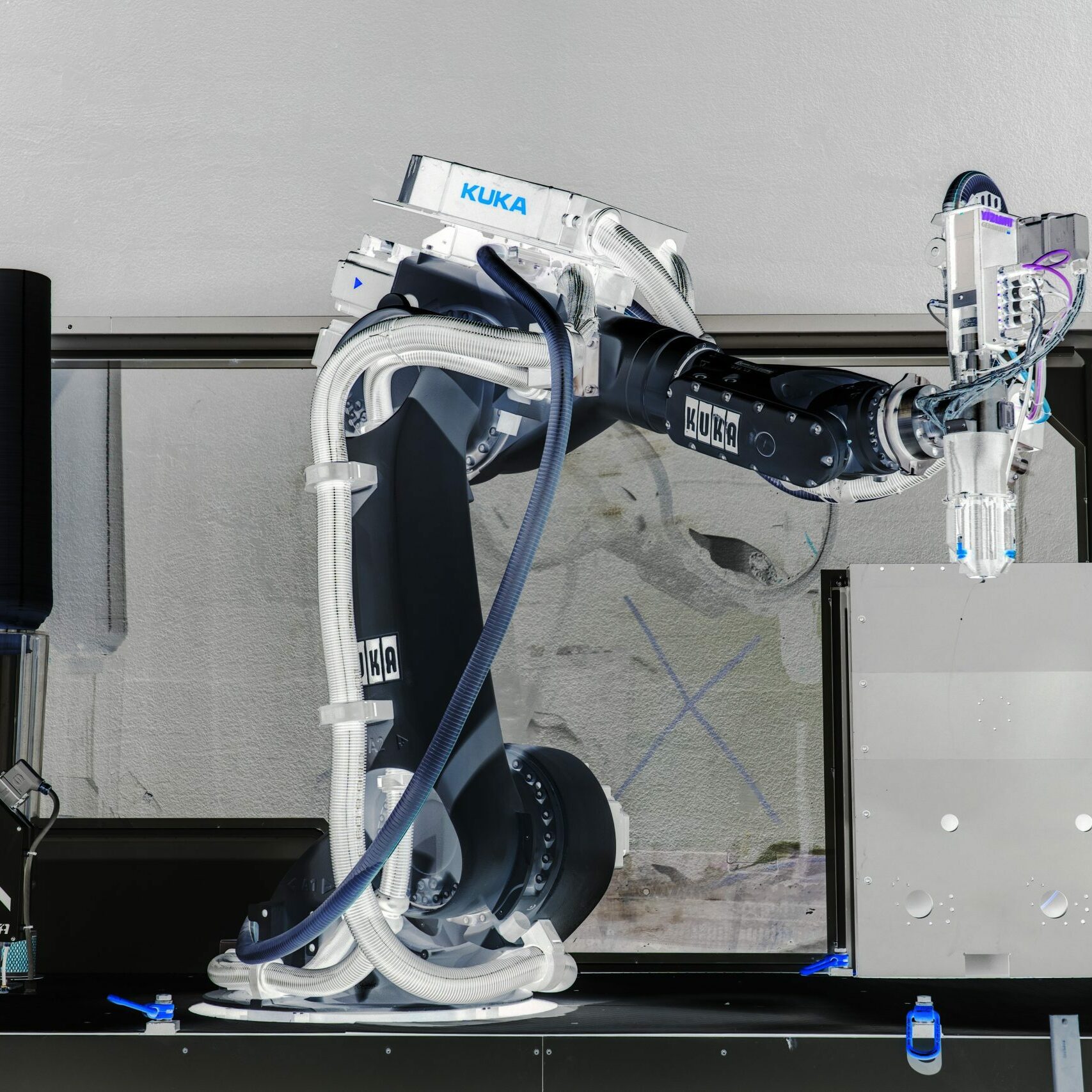

Robotics - Complexity at Scale

Generation 3D is the first 3D printing company to have a fully operational robotic arm 3D printing division in the Middle East.

This allows us to take our large-format 3D printing to a new level. We are able to print large-scale parts for our installations faster than ever. The large robotic print area as well as the print speeds of our robots allow us to take on much larger projects, particularly in the interior design and construction space.

Robotic 3D printers also open up the world of raw materials as we are able to print from a pelletized raw material. This enables Generation 3D to print in fully recycled materials and new organic compounds.

FDM – Beautiful Beast

Our farm of over 50 Fused Deposition Modeling (FDM) machines allows us to 3D print at scale. Our 3D print farm of customized 3D printers gives us the capability to take on the largest of manufacturing tasks for our projects. We operate our machinery 24 hours a day to ensure the most efficient delivery of all our projects.

Whilst FDM machines are common in the industry, our custom machines are not. We have customized machines that allow us to print more complex parts faster. Our projects and capabilities with our customized hardware shock the most experienced 3D printing professionals.

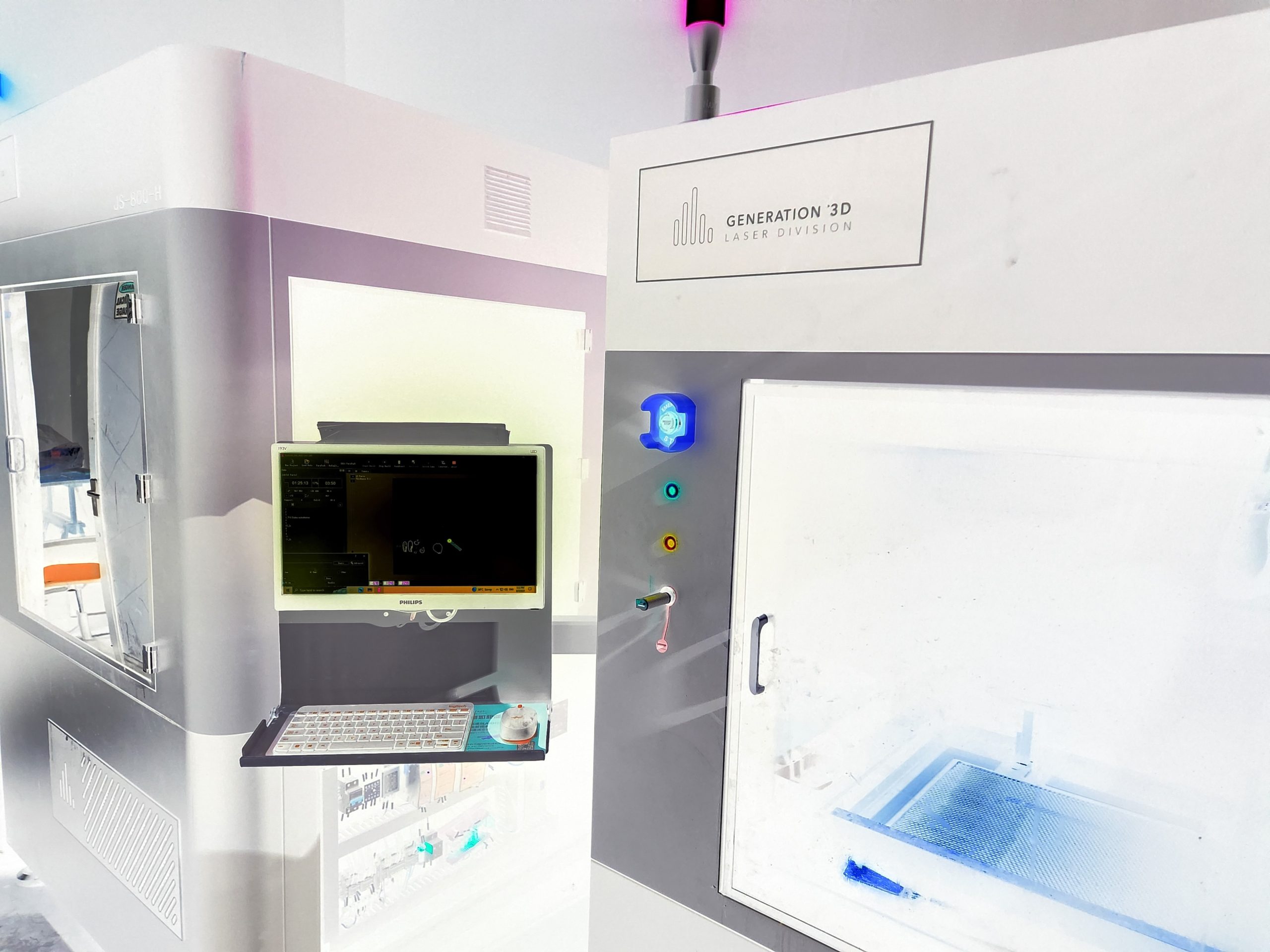

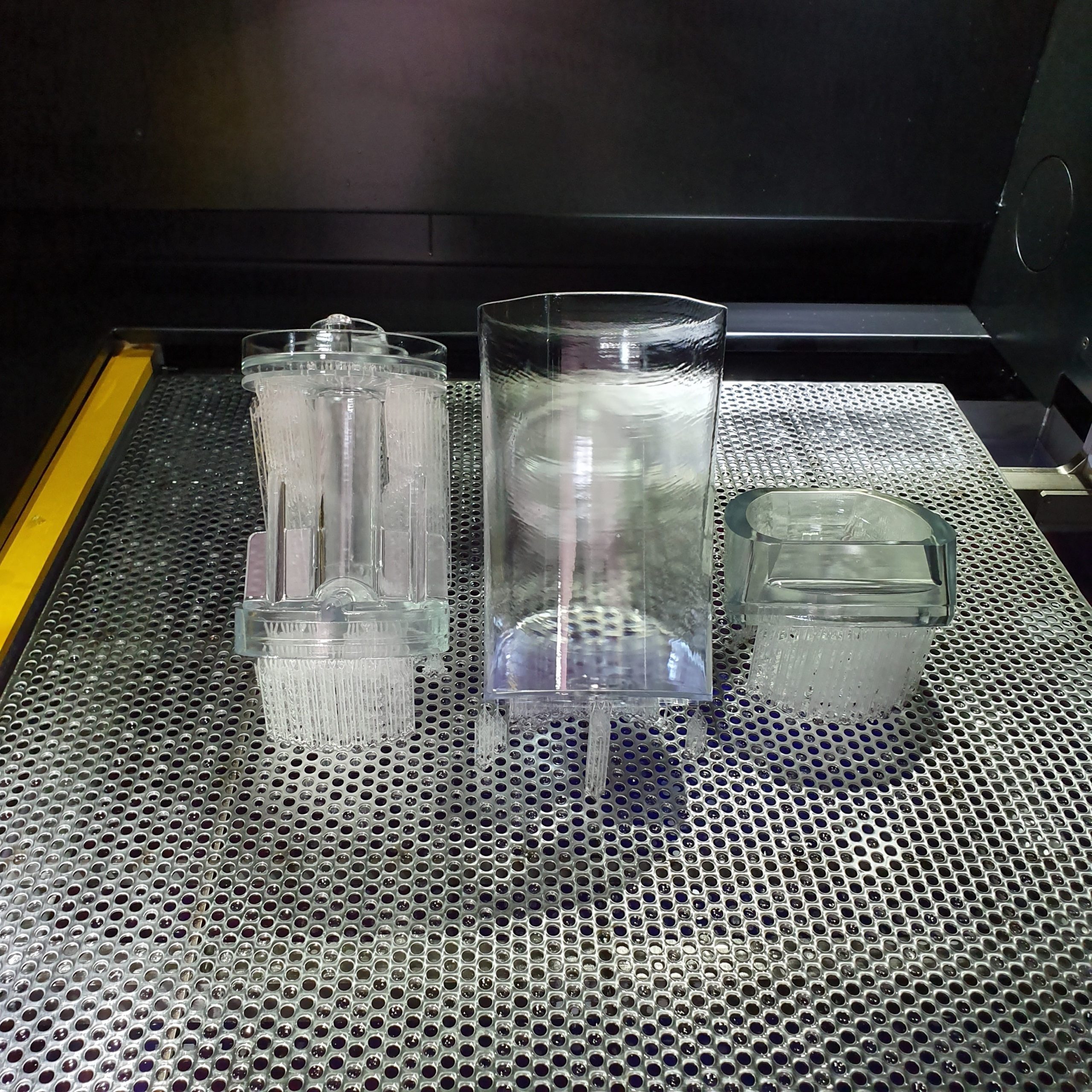

Laser Division – Precision Personified

Our fleet of both SLA and DLP machines allows us to deliver the highest possible detail at scale. With an ability to 3D print at a scale of 16microns, we can produce parts that other manufacturing techniques simply cant.

At Generation 3D we use a range of different resin-based systems ranging from high precision small machines to large SLA machines delivering accuracy at scale. Laser or resin-based systems deliver excellent surface quality and detail as well as delivering transparent or translucent parts.

Software

At Generation 3D, we're not just 3D printing enthusiasts; we're the architects of innovation. We've taken the art of 3D printing to the next dimension, embracing cutting-edge technologies and pushing the boundaries of what's possible. With a relentless focus on parametric design, non-planar 3D printing, and efficient use of 3D modelling software, we're revolutionizing the world of

additive manufacturing.

Parametric Design: Shaping Possibility

Our journey begins with parametric design, a game-changer in the world of 3D printing. This groundbreaking approach allows us to create complex, intricate structures with unparalleled precision. By harnessing the power of parametric design, we can optimize geometries for performance, efficiency, and aesthetics. Whether you're looking to create custom prototypes or intricate art pieces, our parametric design expertise ensures your vision comes to life with unmatched accuracy.

Non-Planar 3D Printing: Defying Gravity

Generation 3D is at the forefront of non-planar 3D printing technology. Say goodbye to the limitations of traditional layer-by-layer printing. With non-planar printing, we can produce objects that defy gravity, resulting in smoother surfaces, reduced material waste, and greater structural integrity. This groundbreaking technique opens up a world of possibilities, from aerospace components to avant-garde sculptures. If you can dream it, we can print it in ways you never thought possible.

Efficiency in 3D Modelling: Where Art Meets Engineering

Our commitment to efficiency extends to 3D modelling software. We understand that time is of the essence, and every project demands precise execution. That's why we employ the most advanced modelling tools to streamline the design process. Our

team of experts is well-versed in leveraging these tools to maximize efficiency, ensuring your project is completed on time and within budget. Whether it's rapid prototyping, bespoke manufacturing, or architectural modelling, our efficient use of 3D modelling software guarantees results that exceed your expectations.

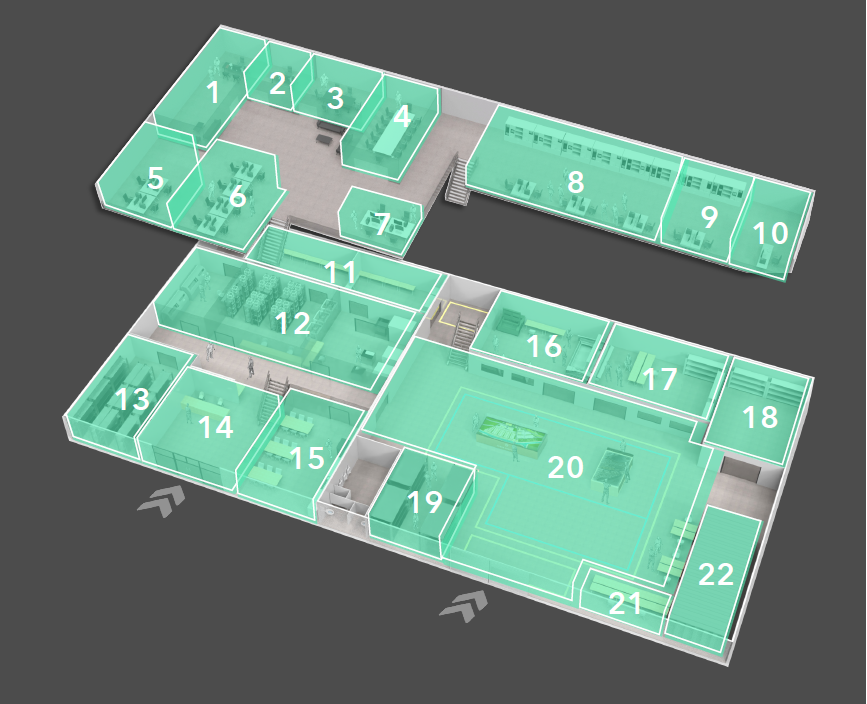

Facility

At Generation 3D, we don't just embrace innovation; we embody it. Our commitment to excellence is showcased through our cutting-edge 13,000-square-foot facility in the heart of Dubai. This world-class facility is the cornerstone of our capabilities, enabling us to deliver complex 3D printing projects from concept to completion entirely in-house.

Our world-class facility is renowned globally and is the benchmark for large-scale 3D printing and design.

A Hub of Creativity and Precision

Our Dubai facility is more than just a workplace; it's a hub where creativity meets precision. Here's how our state-of-the-art facility empowers us to bring your ideas to life:

In-House Expertise:

Our team of skilled professionals, including designers, engineers, and technicians, work collaboratively under one roof. This close-knit environment fosters innovation and ensures seamless communication throughout the entire design and manufacturing process.

Streamlined Workflow:

With every aspect of production under one roof, we eliminate the need for outsourcing or third-party involvement. This streamlines our workflow, allowing us to maintain the highest level of quality control while optimizing efficiency. Our facility is purpose built for 3d printing within the architectural and design space. Our home allows us to deliver our technological capabilities with surgical precision and efficiency.

End-to-End Services:

From the initial design concept to the final product, Generation 3D provides end-to-end services. Whether you require rapid prototyping, architectural models, or intricate interior design elements, we handle every phase of your project with expertise and dedication.

We carry our every part of the process in-house. From our team of designers and architects to finishing and installing the part, we will take care of the process for you.

Quality Assurance:

Our facility is equipped with stringent quality control measures to ensure that every piece we produce meets

our exacting standards. We take pride in delivering flawless results, project after project.