Sustainability.

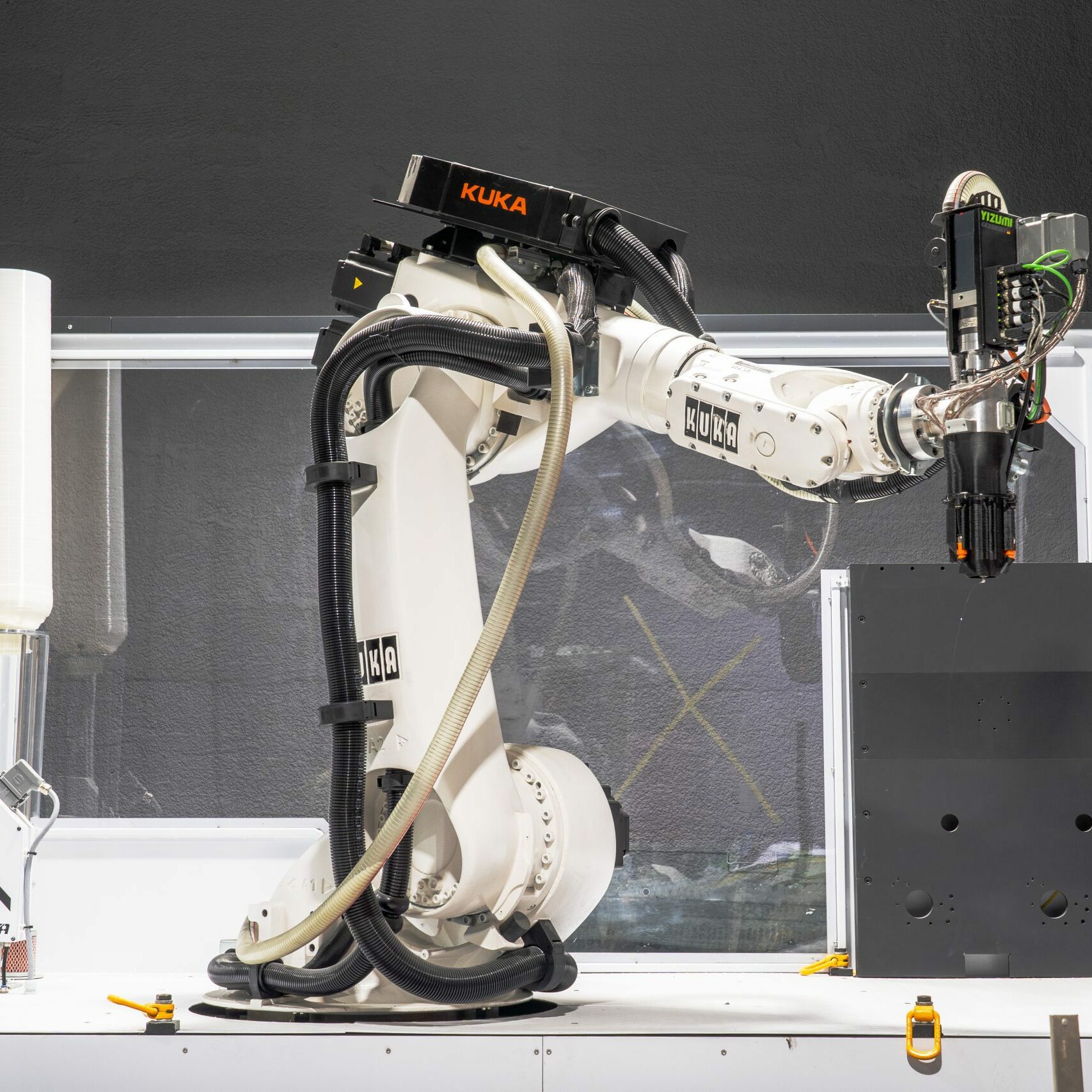

Since day one at Generation 3D our mantra has been “Innovate Sustainably”.

We believe in the sustainability will be the next great innovation for humanity and our next leap forward. The green revolution provides a very real need and therefor opportunity for us as a business.

How things are designed, manufactured and built has a huge role to play in this. From what energy we use to power our offices, to our raw materials, manufacturing and construction has a huge way to go. Frankly many of the old guard simply cant change as their business model relies on it…that’s where we come in.

At G3D we believe we have the power to change the world and grow a global leading business in the meantime. We see the Green Revolution as an open market to be shaped for the better when it comes to manufacturing and construction.

Materials

At its most basic we transform raw materials into incredible products and projects using 3D printing, so it makes sense to start with the raw materials.

Our most commonly used material is Polylactic acid (PLA), a plastic substitute made from fermented plant starch (usually corn) is quickly becoming a popular alternative to traditional petroleum-based plastics.

PLA—which is carbon neutral as it comes from renewable, carbon-absorbing plants—as yet another way to reduce our emissions of greenhouse gases in a quickly warming world. PLA also will not emit toxic fumes when incinerated.

Processing of PLA to become a useable raw material is also much more efficient than standard petro plastics, reducing PLA uses 65 percent less energy than producing conventional plastics, according to an independent analysis commissioned by NatureWorks. It also generates 68 percent fewer greenhouse gases, and contains no toxins.

To top it off for our customers…corn-based plastics are starting to look cheap, now that oil prices are so high.

Better than Recycling

As previously discussed our BioPlastics are a huge leap forwards in materials particularly compared to other plastics or manufacturing techniques, but we can go one step further with recycling and composting.

We encourage all our clients to recycle their 3D printed parts where possible. All PLA materials are recyclable however we can go one step further. Composting is even more efficient and sustainable as the PLA procedure to harvest the BioPlastic is carbon neutral.

Also, PLA is compostable, meaning that it will break down under certain conditions into harmless natural compounds. That could take pressure off the nation’s mounting landfills, since plastics already take up 25 percent of dumps by volume.

PLA will not biodegrade under natural conditions however (so don’t worry it wont disappear on you!) however when sent to industrial composting plants PLA will compost into harmless natural gas water and lactic acid which is a naturally occurring, harmless, organic acid.

We would love our clients to start composting their PLA parts and we will be on hand to advise on how to do so when needed.